ONGUARD’S SEISMIC

ENGINEERING EXPERTISE

ONGUARD is the earthquake protection expert for aboveground storage tanks and our experience has shown a holistic design approach is required to ensure dependable seismic performance. Our seismic system, which considers the tank, anchors, foundation, and connected infrastructure, is the most innovative on the planet, and its performance was proven in a M7.8 earthquake.

The ONGUARD system can be applied to new construction or retrofitted to existing tanks to introduce dependable earthquake protection.

OUR ANCHOR & DESIGN APPROACH

The ONGUARD system uses a capacity design approach using its patented OG PRO ductile anchors. These anchors concentrate damage from seismic loading into one small replaceable component, and provide protection to the tank, its contents, and attached infrastructure.

The replaceable component is machined to meet 100% of the structural demand and designed to retain its ductility after a design level event. It’s a highly resilient component that can withstand events far in excess of design level.

Earthquake engineering 101, applied specifically for liquid storage tanks.

CODE COMPLIANCE

The ONGUARD system is designed using globally-recognized standards and guidelines including:

- API 650

- ASCE 7

- AWWA D100

- NZS1170.5

- NZSEE ‘Seismic Design of Storage Tanks’ 2009 Guideline

Our Professional Engineers (PE) and Chartered Engineers (CMEngNZ) ensure compliance with local building codes and international best practice is met. We provide certification for the entire structural system to assist with the permitting process.

OUR RESEARCH

ONGUARD developed its own advanced research to better understand the actual behavior of an aboveground liquid storage tank during an earthquake. This research found a hybrid antisymmetric, ductile-elastic, and ductile-plastic anchor force distribution best matches the actual forces that the base of a tank encounters during an earthquake. ONGUARD adopts this research as the basis for its designs, guaranteeing accurate and 100% efficient solutions.

We're more than happy to answer questions about this pioneering design approach.

CONTACT US

OUR ENGINEERING

ONGUARD engineers its seismic anchoring system to new construction as well as retrofit projects. Each retrofit project starts with an assessment of the existing facility by ONGUARD's engineers.

NEW CONSTRUCTION & RETROFIT DESIGNS

For each project, ONGUARD's engineers take responsibility for the structural design of the entire structural system, and specify made-to-order OG PRO anchors which are customized for the tank configuration and seismic hazard of that particular location.

ONGUARD provides PE-stamped or CMEngNZ-signed documentation including detailed calculations for the structural design.

If building permits are necessary, ONGUARD stamps and submits all documentation and construction drawings. In New Zealand, we issue a signed Producer Statement PS1 (Design).

ONGUARD delivers an end-to-end service by overseeing installation to maintain quality assurance, and offers a 3-yearly inspection schedule to provide the ultimate peace of mind.

NEW CONSTRUCTION

New aboveground liquid storage tanks must be built to handle standing gravitational loads, and the seismic ground accelerations of an earthquake.

To ensure your aboveground storage tanks withstand an earthquake, our engineers provide design specifications for anchorage and tank shell construction, as well as the foundation and any supporting structure. Displacements of ONGUARD tanks are minimal, nevertheless we make sure that connections to other infrastructure can accommodate these displacements. ONGUARD's design protects every single component of the tank system.

RETROFIT

Existing older tanks with traditional - or sometimes no - anchoring pose a great risk to your business as they may fall well short of modern design code requirements. Non-compliant tanks and anchors leave your tanks susceptible to severe damage or collapse in an earthquake.

ONGUARD anchors replace your existing tank anchors with minimal impact to your operation or tank aesthetic. They protect all elements of the existing tank system from damage by introducing much-needed - and code-mandated - ductility and resilience.

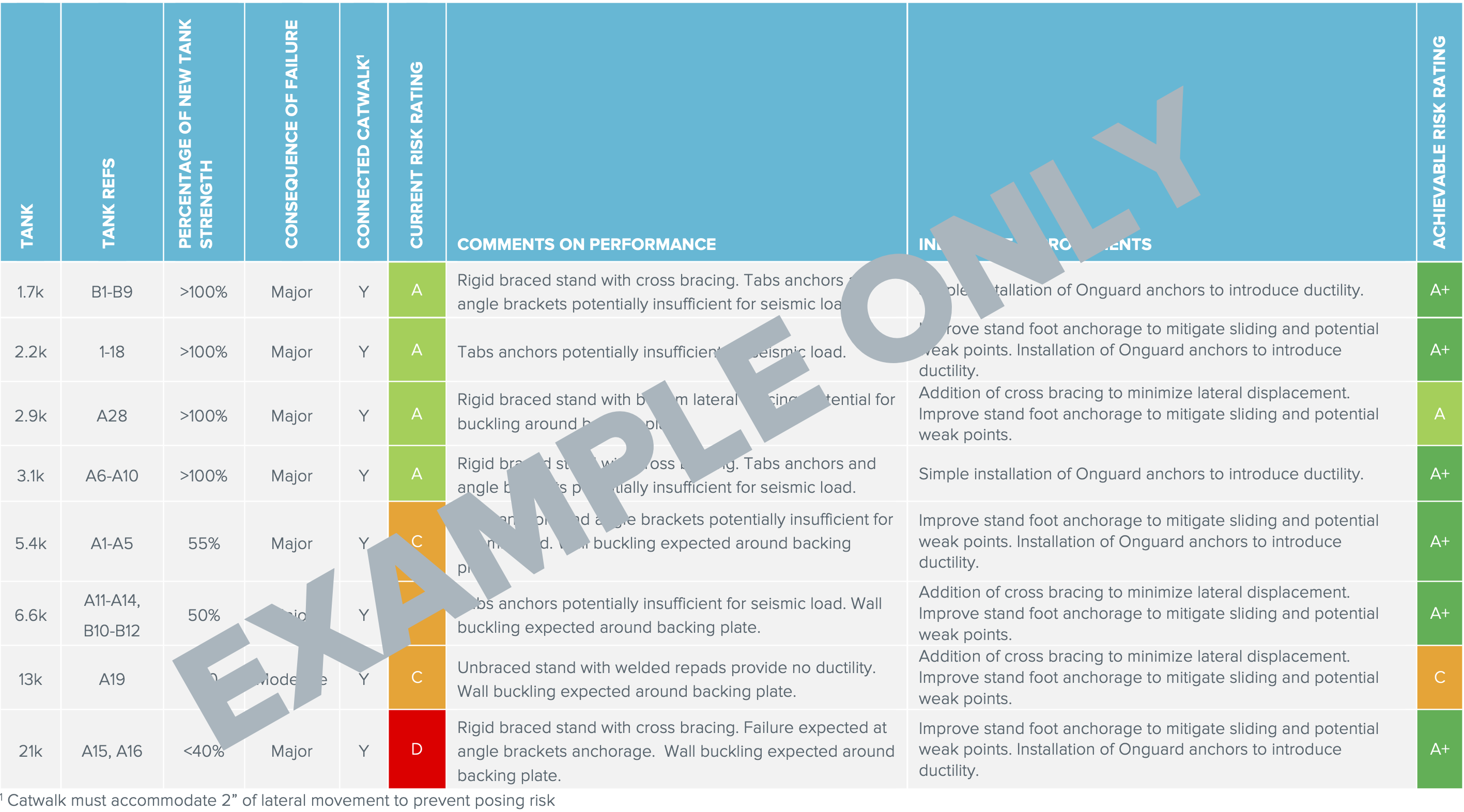

FACILITY RETROFIT EVALUATION

Retrofit projects start with ONGUARD providing a detailed assessment of your existing aboveground storage tank facility.

- ONGUARD engineers visit the facility and examine existing drawings to gather data such as tank geometry, material thicknesses, supporting structure construction, foundation construction, and site seismicity.

- Using this gathered data, the engineers calculate the earthquake strength of the existing tanks. The level of risk to property and the level of financial risk are assessed for each tank or tank group.

- Assessed risk to property and improvement solutions are presented on a scale of A+ through D clearly identifying the greatest threats. Prioritizing work based on the level of importance allows you to bring your tanks up to current safety standards on a schedule that works best for your business.

- Assessed financial risk is presented in a table comparing the probability and economic implications of current tank failure versus the same tank protected by the ONGUARD system. This table provides a second perspective of the risk posed.

- A Seismic Risk Evaluation Report summarizes the collected data, the seismicity of the facility location, and all of these assessments and specifications.

- Upon completion, an ONGUARD engineer will walk you through the report, review your priorities and discuss next steps.

In facility retrofit evaluations, ONGUARD provides a full report which assesses risk to property and presents improvement solutions. This report helps to identify the greatest threats and prioritize future work.

In a typical retrofit application, ONGUARD replaces traditional anchors with new OG PRO anchors.

LAB TESTED.

EARTHQUAKE PROVEN.

ONGUARD knows its system will perform exactly as intended during a seismic event and its aftershocks; the ONGUARD system is both lab tested and earthquake proven.

LAB TESTED. EARTHQUAKE PROVEN.

LAB TESTED

ONGUARD tested the performance of its OG PRO anchors under simulated seismic loading in a professional laboratory.

In 2021, the OG PRO MKIII series anchors were tested under quasi-static cyclic loading, verifying their performance. Prototype testing was completed in accordance with FEMA 461 (2007) using a displacement-controlled loading protocol. The OG PRO MKIII anchors were rigorously evaluated and certified to be in compliance with the 2018 and 2015 International Building Code (IBC) by the International Code Council Evaluation Services (ICC-ES).

EARTHQUAKE PROVEN

The Magnitude 7.8 Kaikōura Earthquake that struck New Zealand in 2016 put the ONGUARD system to the ultimate test. Accelerations exceeded design level by up to 60%, and over 300 tanks protected by ONGUARD survived two minutes of violent shaking with zero damage. No insurance claims were made involving ONGUARD-protected tanks.

In this real-life scenario, the ONGUARD system was proven to perform exactly as intended and saved over 15 million gallons of product. The New Zealand wine industry prevailed, thanks in no small part to ONGUARD.

Request Technical Papers on Winery Earthquake Performance

OUR PATENTED

ANCHORING PRODUCT

The most critical component of the ONGUARD system is the ductile OG PRO seismic anchors. The anchors are available in a variety of sizes to accommodate any size of liquid storage tank.

OG PRO ANCHOR TECHNICAL INFORMATION

ANCHOR

OG PRO 10

OG PRO 23

OG PRO 33

OG PRO 51

OG PRO 81

OG PRO 117

OG PRO 172

OG PRO MAX

kN

9.2 - 11.1

22.6 - 26.3

22.1 - 36.9

49.6 - 58.3

76.3 - 90.9

103.6 - 141.6

152.4 - 203.6

263.2 - 326.1

kips

2.1 - 2.5

5.1 - 5.9

5.0 - 8.3

11.2 - 13.1

17.2 - 20.4

23.3 - 31.8

34.3 - 45.8

59.2 - 69.2

kiloliters (NZ tanks)

2 - 10

5 - 40

20 - 60

40 - 100

60 - 120

80 - 150

100 - 240

160 - 500+

gallons (US tanks)

500 - 2,000

1,000 - 10,000

5,000 - 20,000

10,000 - 50,000

30,000 - 80,000

50,000 - 100,000

80,000 - 200,000+

150,000 - 300,000+

* The strength of the yielding fuse is sized for the specific tank application to create 100% efficient designs and ensure protection of the entire liquid storage tank system. ** Selection of the most appropriate anchor is driven by multiple factors including the height-to-radius ratio of the tank, site seismicity, and any existing foundation constraints. CONTACT US FOR MORE INFORMATION

MOHAWK SOFTWARE

Our unique and innovative design approach is available through MOHAWK, a web-based platform which streamlines the design and proposal process. Engineers, tank builders and designers run designs with this easy-to-use tool. All the pertinent design information is processed to provide the most efficient solution to protect your liquid storage tank, and output reports are used in applications for building approvals. An ONGUARD engineer is always available to assist with this process and will review and approve the proposed designs.

GO TO MOHAWK

CASE STUDY: 8,000 GALLON SAKE TANK ON CALIFORNIA’S CENTRAL COAST

ONGUARD designs a seismic anchorage system for an existing aboveground storage tank on a stand

SELECTED CASE STUDIES

Each case study below provides a deeper look into ONGUARD’s innovative design approach and superior system performance.

TITLE

335,000 gallon diesel tank in Southern California

ONGUARD designs a seismic anchorage system for a

new aboveground liquid storage tank on a slab

65,000 gallon wine tank on California’s North Coast

ONGUARD designs a seismic anchorage system for a

new aboveground storage tank on a skirt

8,000 gallon sake tank retrofit on California’s Central Coast

ONGUARD designs a seismic anchorage system for an

existing aboveground storage tank on a stand

AUTHOR

Olivia Vidmar

Olivia Vidmar

Olivia Vidmar

DOWNLOAD

INNOVATIVE

ANCHORING

TECHNOLOGY

ONGUARD’s anchoring system uses a ductile energy dissipation device to protect the integrity of the tank, its contents, connections, and supporting structure throughout an earthquake and its aftershocks.

ESTABLISHED

ENGINEERING

BACKGROUND

ONGUARD was founded in Christchurch, New Zealand – a city with a reputation for producing some of the world’s finest structural designers and earthquake engineering techniques.

PROVEN SEISMIC PROTECTION

THE PATENTED ONGUARD SYSTEM DISSIPATES SEISMIC ENERGY IN A CONTROLLED MANNER, KEEPING ABOVEGROUND LIQUID STORAGE TANKS AND THEIR CONTENTS PROTECTED.